Flexible 95A

Flexible 95A filaments are made from TPU (Thermoplastic Polyurethane) and have strong rubber-like qualities. Compared to harder TPU grades, 95A is softer, more elastic, and offers excellent flexibility. It’s ideal for parts that need to bend, stretch, compress, or absorb impact while still remaining durable. Common applications include phone cases, gaskets, bumpers, grips, protective covers, toys, and various household or automotive components.

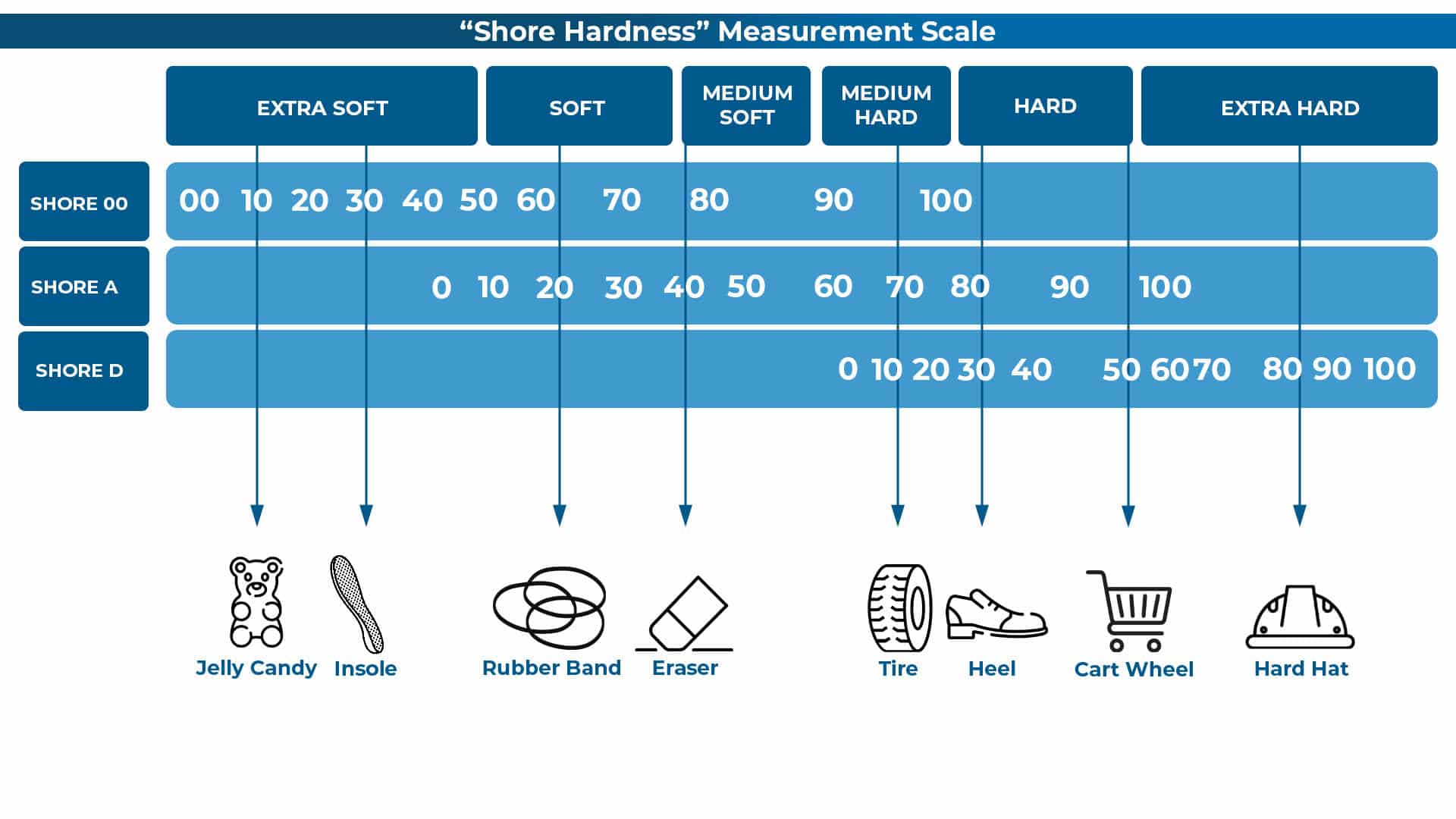

Flexible filaments are classified using the Shore hardness scale, which ranges from 0 to 100 and is divided into categories such as Shore A and Shore D. Lower numbers mean a softer, more flexible material. TPU with a Shore hardness of 95A feels similar to a firm rubber — flexible and bendable but still strong enough to hold shape under load.

Disclaimer: If you hear popping or crackling during printing, the filament has absorbed moisture. Dry it before use for best results. A filament dryer box is recommended.

Printing recommendations:

- For the best results, print at 220–240°C.

- Recommended printing table temperature is 40–60°C.

- Print at a slow speed of 10–30mm/s.

- Use a glass bed, PEI sheet, Kapton, or Blue tape for the build platform with 3Dlac spray.

*Ideal temperature may vary when using different printers.

You can access the Technical Data Sheet here.