A new era of 3D printing is here

At AzureFilm, we’re always thrilled to bring you the latest in 3D printing innovation, and the Bambu Lab H2C is no exception. Building on the success of the H2S, the H2C introduces a whole new level of multi-material and multi-color printing, combining speed, precision, and efficiency in ways that were previously impossible.

What makes the Bambu Lab H2C stand out

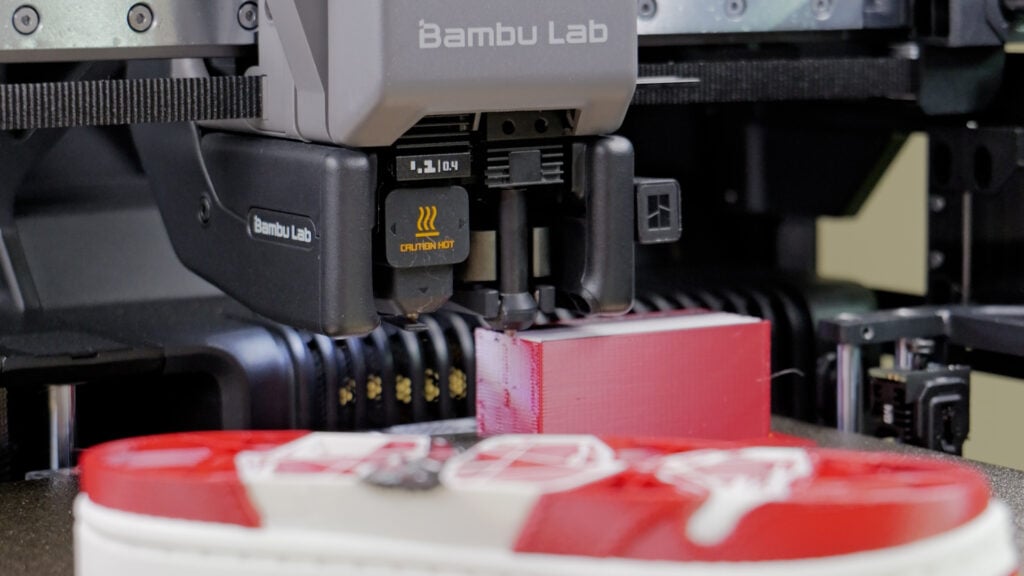

The Bambu Lab H2C represents a significant leap forward in 3D printing technology, primarily thanks to its Vortek Hotend Change System. This innovative system allows the printer to switch automatically between multiple hotends, enabling up to seven colors or materials in a single print with virtually no purge waste.

Unlike traditional multi-material setups, the H2C uses magnetic, contactless hotends that intelligently select the optimal nozzle for each filament, drastically reducing human intervention and material waste.

Additionally, the H2C features a smart software ecosystem capable of predicting and adjusting for printing conditions on the fly, while a quad-camera and sensor system ensures consistent quality from start to finish.

This combination of advanced hardware and intelligent software makes the H2C more than just a printer — it’s a versatile production hub that allows for complex designs that were previously difficult or time-consuming to achieve.

What about the Bambu Lab H2S?

The Bambu Lab H2S, on the other hand, is designed for users who prioritise large build volumes and reliability. With a build area of 340×320×340 mm, it can handle sizable and complex models with ease.

It offers high-speed printing, a heated chamber, and the ability to handle engineering filaments up to 350 °C, making it an excellent choice for both hobbyists and professionals. The H2S also includes AI-assisted sensors and vision systems to reduce print failures, and optional laser or cutting modules can expand its functionality even further.

While the H2S excels at streamlined, single-material or dual-material prints, it doesn’t include the H2C’s advanced Vortek system, which means it still relies on traditional purging when printing multiple materials or colors.

Comparing H2C and H2S

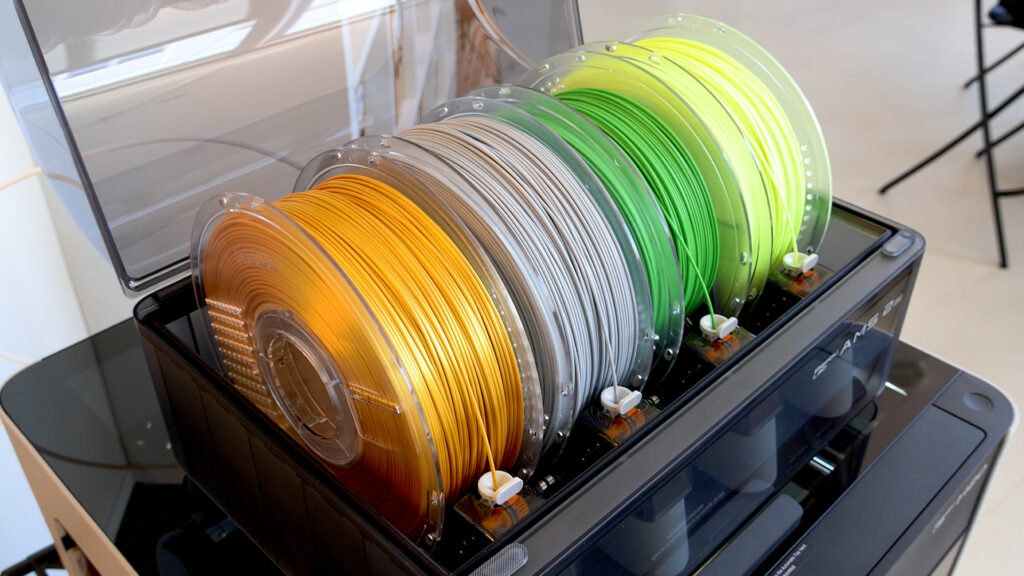

When comparing the two, the H2C shines in situations where multi-material, multi-color printing, and waste reduction are crucial. Its automatic hotend swaps and intelligent AMS integration allow for complex, colorful prints with minimal effort and material loss. This makes it ideal for prototyping intricate designs, producing functional parts with multiple materials, or creating finished pieces that combine both strength and aesthetics.

The H2S remains a strong, versatile workhorse for those who need large build volumes, high reliability, and engineering-grade material support. It’s perfect for users focused on straightforward, high-quality printing without the additional complexity of multiple toolheads.

In short, the H2C is about flexibility and innovation, while the H2S emphasizes capacity and reliability. Both printers are excellent investments, depending on your specific printing needs.

H2C vs H2S: side‑by‑side comparison

| Feature | Bambu Lab H2C | Bambu Lab H2S |

| Intended Use | Premium multi‑material, multi‑color, reduced waste | Large format, high‑performance single/nozzle printing |

| Multi‑Material Support | Up to 7 filaments with Vortek + AMS | AMS optional (dual‑material or standard AMS)+ |

| Nozzle System | Automatic hotend change system (magnetic, contactless) | Single nozzle (all‑metal, swappable) |

| Build Volume | 330×320×325 mm | 340×320×340 mm |

| Max Nozzle Temp. | ~350 °C | ~350 °C |

| Chamber Heating | ~65 °C active | ~65 °C active |

| Motion / Speed | High-speed CoreXY, rapid acceleration | High-speed CoreXY, rapid acceleration |

| Sensors / Cameras | Extensive (quad-camera + multiple sensors) | Multiple cameras + sensors |

| Software / Monitoring | AI‑assisted print monitoring | AI‑assisted monitoring with optional Vision Encoder |

| Material Compatibility | PLA, PETG, TPU, composites (PA, PC, GF/CF) | PLA, PETG, TPU, composites, engineering filaments |

| Optional Upgrades | AMS units, laser modules, cutting | AMS units, laser modules, cutting, Vision Encoder |

| Cost Level | Higher (premium system & hotend tech) | Lower (more affordable base & upgradeable) |

Which one should you choose?

We believe both the H2C and H2S offer unique advantages. If your goal is to push the boundaries of multi-material creativity and reduce waste, the H2C is the printer for you. If you’re focused on large-scale engineering prints or prefer a tried-and-tested workflow, the H2S remains a reliable choice.

Whichever model you choose, pairing your printer with high-quality filaments from AzureFilm ensures the best results. Both printers represent the future of desktop manufacturing and creative fabrication, allowing makers and professionals alike to bring complex designs to life with precision and efficiency.

Previous post

Previous post