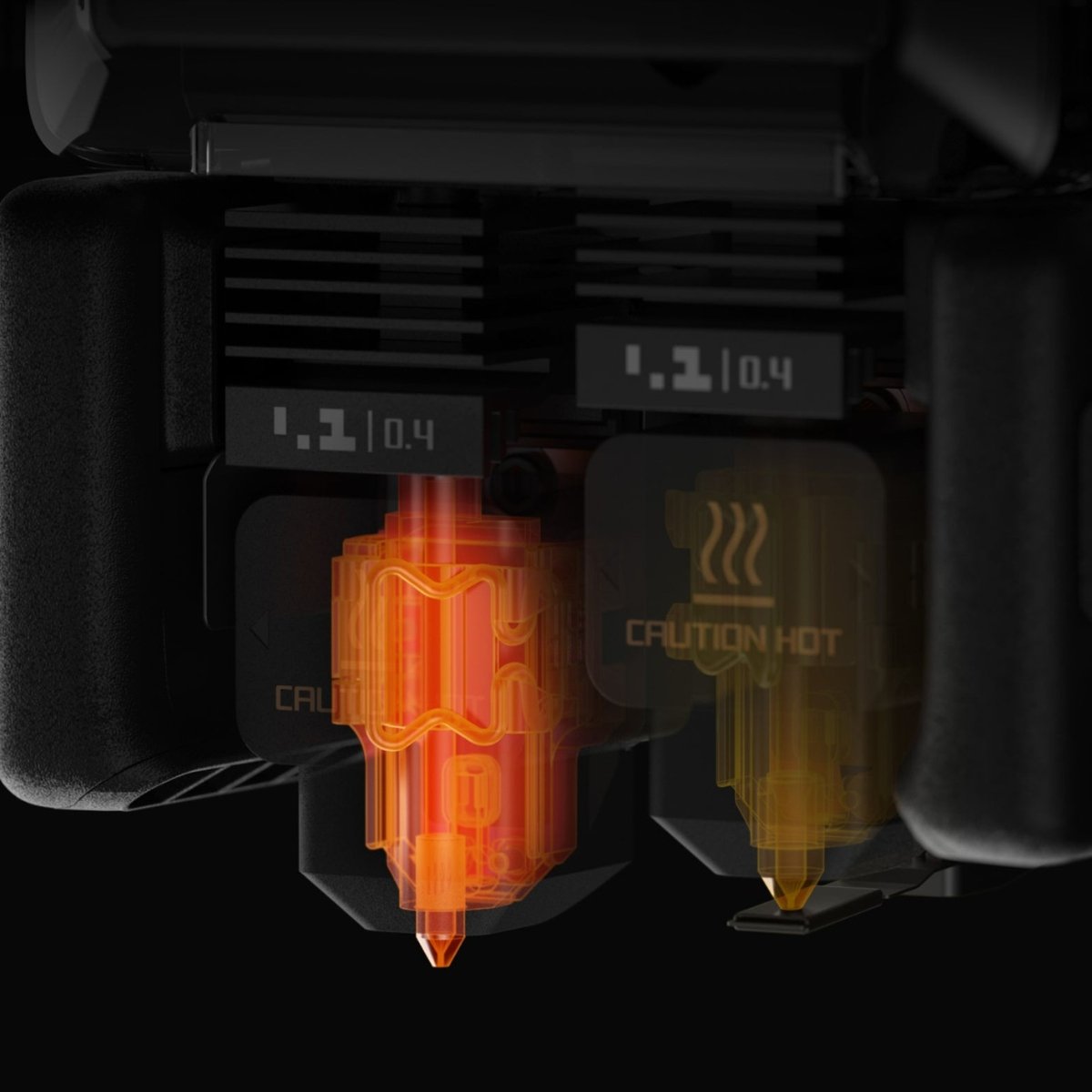

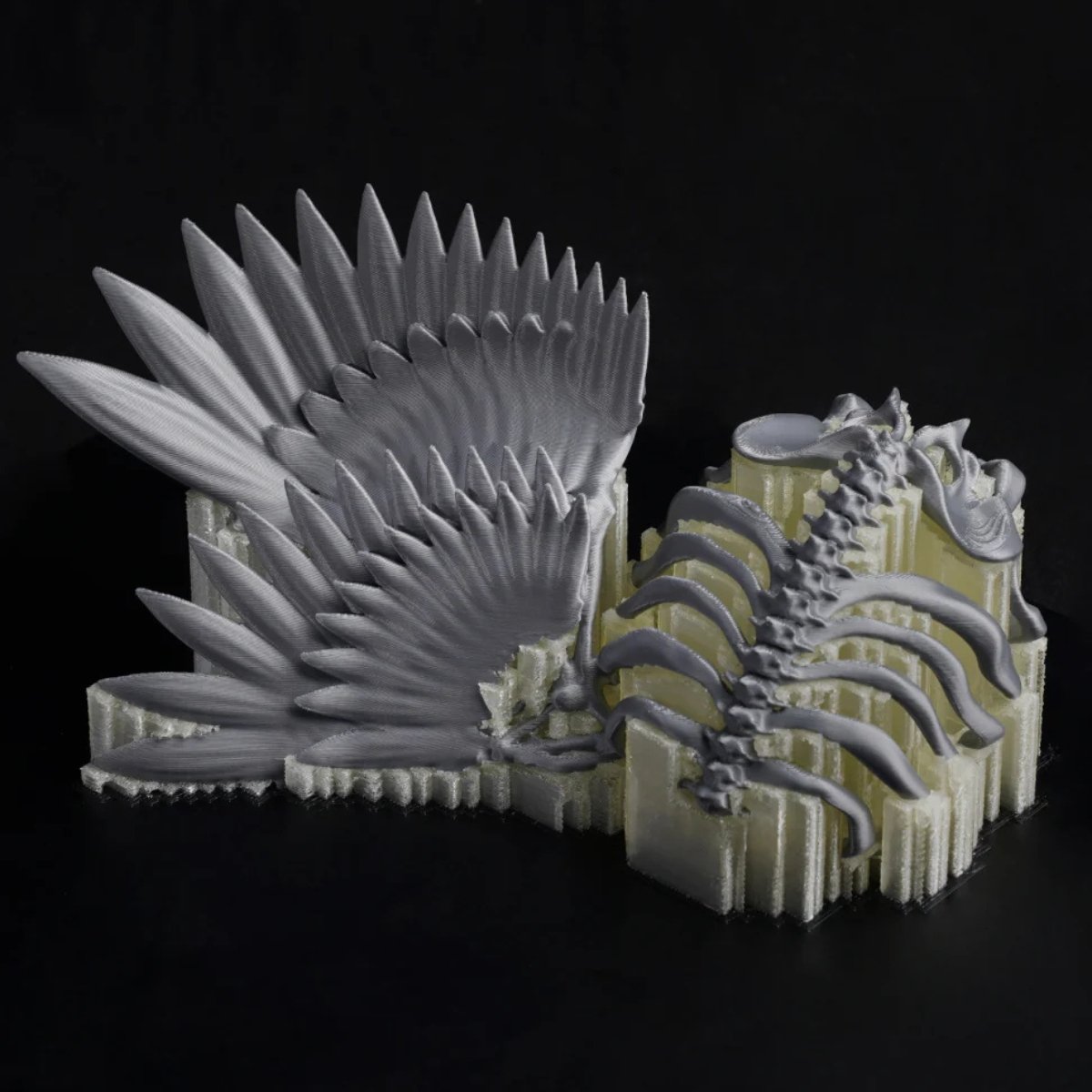

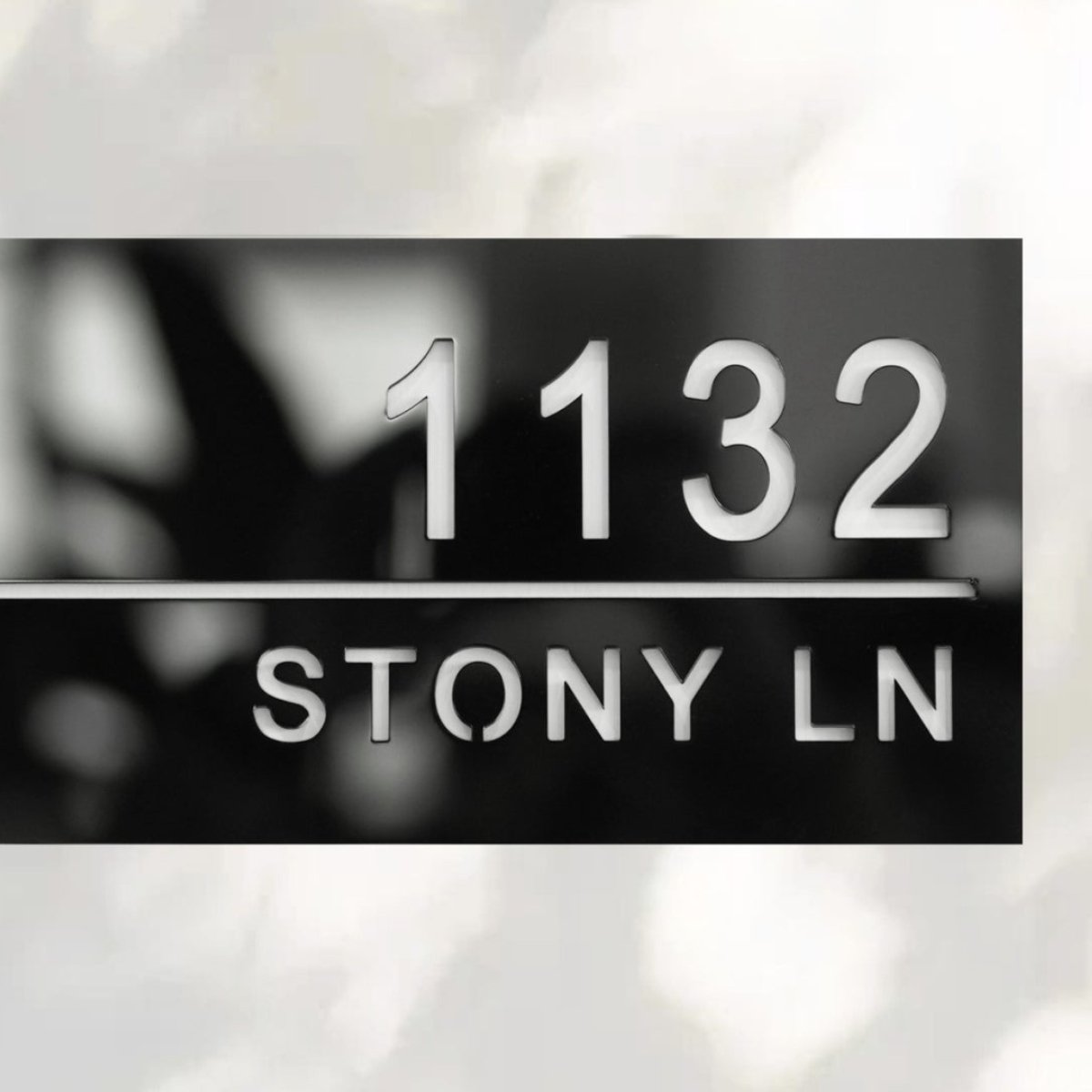

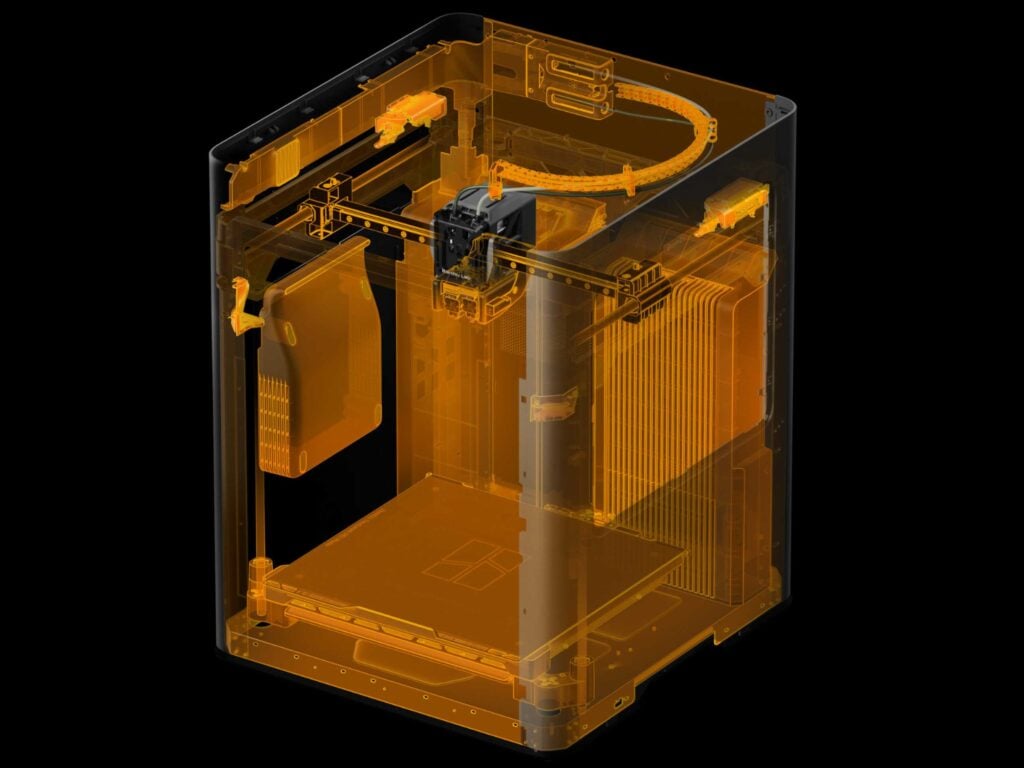

Bambu Lab H2D Combo + 4x Refill PETG Black + 4x Master Spool

Bambu Lab H2D Combo in combination with 4 kilograms of AzureFilm Refill PETG Original Black filament & Master Spool 4-pack.

Important: The 10W/40W Laser and Cutting Module is optional. The H2D in our offer does not include the laser.

Delivered in 7 - 14 days

Delivered in 7 - 14 days