Support Filaments: Everything you need to know

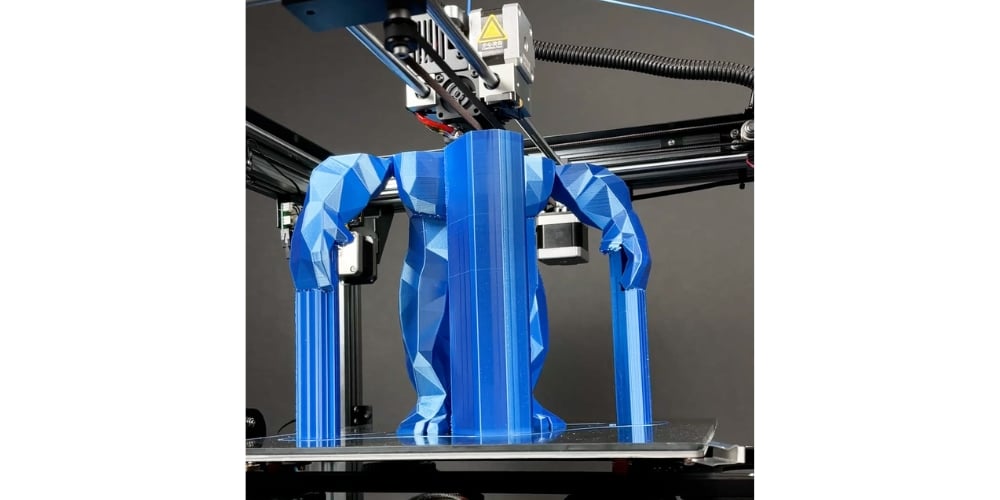

When it comes to producing intricate 3D prints, the significance of support structures or support filaments is incomparable. Thanks to them we can apply compound geometries all the while keeping the aesthetics of the design intact. In this article, we are going to confer about the best support filaments for making support structures, available options, best practices, and troubleshooting methods. So, give this article a thorough read for making sophisticated 3D prints.

Introduction to support filaments

What are support filaments?

Support filaments or support structures are temporary constructs printed alongside the main model to provide stability to the print. If the design of the model includes complex geometries or overhangs, it needs appropriate support to prevent drooping or collapsing. Support structures are there to retain intricate shapes and features in place till the printing process finishes.

After analysing the design and the set parameters, the slicing software specifies the areas requiring support and prints them with the original model. These structures are manually removable or soluble in water.

Importance of support structures in 3D printing

Support structures are extremely important to stabilise certain parts of the print. They ensure the precise replication of complex details and promote better-quality models. Without support filaments, it would be nearly impossible to comprehend intricate figures in 3D prints. Support structures brought versatility to the technology of 3D printing, amplified its competence, and endorsed the possibility of manufacturing groundbreaking objects.

Types of support materials

Depending on the design specifics, several support filaments are frequently used in 3D printing and they are:

PVA (Polyvinyl Alcohol)

Polyvinyl Alcohol AKA PVA is a water-soluble and highly compatible type of support filament commonly used for its excellent support feature. It dissolves in the water effortlessly leaving a clean print. You can use PVA with an array of printing filaments.

HIPS (High Impact Polystyrene)

High Impact Polystyrene is another highly compatible support filament that dissolves in d-limonene with no issue leaving an even surface finish.

Breakaway support filaments

So, basically, you use the exact filament selected for the main design to create support structures, and when the print is completed cut them away or physically break them. They are quite easy to remove and great for support.

Other types of support filaments

Apart from the above-mentioned support filaments, people also use:

Nylon

Nylon is also popular as a support filament since they provide good support to overhangs and is soluble in apt solvents. You can also remove the supports manually.

Metal support

This type of support is used in the 3D printing process such as selective laser melting for supporting metal parts. Generally, similar metal powder used for printing the main print is used for making these support structures. These metal supports are easily removable with abrasive blasting or EDM.

Brief overview of additional support filaments available

Dissolvable support resins

Rasin filaments are used as support filaments for technologies such as digital light processing. Certain solvents are used in dissolving resin support structures.

FDM support filaments

In the FDM printing process, FDM-compatible filaments such as ABS or PLA are used in making support structures. After printing the object, you can break away these support structures.

Heat-resistant support materials

Technologies such as selective laser sintering need high-temperature thermoplastics such as PEI for printing support structures.

Working with PVA

You need to keep in mind a few things such as print settings or ways of support removal while printing support structures for a model. In this section, we are going to discuss the best ways to work with PVA.

Print settings and considerations

PVA print temperature: Though the print temperature can vary depending on filament brands, the ideal temperature normally ranges from 180 to 210 degrees Celsius.

Bed adhesion: For better bed adhesion, use a heated build platform and clean it before printing. You can also use PVA-based glue so the filament sticks to the surface better.

Print speed: It is best to keep the speed slower, ideally around 20 to 50 percent of the main filament while printing support structures with PVA. It ensures better adhesion, and accurate deposition, and retains structural integrity.

Best practices for PVA support removal

To easily remove the supports, do the following:

- Submerge the model in water so the supports dissolve in it.

- Brush the supports to speed up dissolution.

- Change the water when it gets cloudy with melted PVA.

- Rinse the model and let it dry nicely

- Apply post-processing techniques for a better surface finish.

Tips for optimising PVA support structures

Use support filaments where needed. Don’t go overboard with them since they can elongate the printing time and waste filaments. The ways to optimize PVA support include:

- For retaining structural integrity, adjust support density in the slicing software.

- To promote stability and better adhesion enhance the area of support interface.

- Print slower for better adhesion and deposition.

- Increase the threshold of the overhang angle.

- Adjust the print temperature to lower the chances of stringing

- Monitor the support printing process and resolve issues.

Choosing the right support filament

Factors to consider when selecting a support filament

It’s crucial to choose a compatible filament for printing supports otherwise the removal process gets difficult. Factors to consider while choosing the right filament are

- Ensure the support filament is compatible with the primary filament.

- Assess the ease of dissolution of the filaments or post-processing steps.

- Choose a support filament that easily sticks to a print object.

- To avoid clogging problems, the support filament and primary filament should have similar or close printing temperatures.

- Evaluate the mechanical strength of the support filament and see if it matches the printing requirements.

- Some support filaments are great for fast prototyping while others are good for detailing. Thus, choose a support filament perfect for the print design.

Compatibility with printer and main filament

Support materials should have enough compatibility with the primary filament and with the printer else to confirm the stability of the supports and smooth support removal. Make sure your printer can take on the temperature needed to print with the support filament and is apt for dual extrusion.

Again, the concurrence of the support material with the main filament means improved adhesion between the main print and the support. So, choose a filament that would bond properly with the main model.

Specific use cases and applications

Support structures are highly used in printing delicate models in different industries. Because of them, we can print complicated models. Using supports is very common in industries like automotive or aerospace where the designs are often too complex. They are also largely used in the medical industry for producing prosthetics, anatomical models, or surgical guides.

These support structures are also popular among students and architects for making architectural models and sculptures.

Storage and handling of support filaments

Storage recommendations to prevent moisture absorption

- Keep support filaments in a vacuum-sealed bag or an airtight container.

- Put desiccant packs inside the storage container for keeping the filament dry.

- Store the filaments in a cool and dry place away from sunlight.

- Install a humidity monitor in the storage room so you can act faster if the temperature changes.

- Invest in filament dryers or dry boxes utilized for soaking up excess moisture and keeping the filament dry.

Proper handling techniques to maintain filament integrity

- Preserve support material in an airtight container and drop some desiccant packs so the environment inside remains dry.

- Use gloves as directly touching the filament can transfer moisture or oil to the filament.

- Keep the nozzle clean for better filament extrusion.

- Make sure the filament spool is placed accurately to avoid binding or tangling.

- To retain the filament quality, make sure the print environment stays stable.

Troubleshooting issues

Some issues are fairly common when printing support structures and they are not much different from regular 3D printing. These are:

Adhesion issues

Support filaments often fail to adhere to the build plate when it’s not heated enough, levelled properly, or has debris on it. To troubleshoot this issue, keep the bed clean, use adhesive aids such as hairsprays, and ensure proper levelling.

Stringing

High print temperature and wrong retraction settings are the cause for stringing and calibrating the print speed, temperature, and retraction distance can fit this issue.

Clogging

Filament residue left from previous printing often causes this problem which you can troubleshoot by fine-tuning print temperature, using the right size nozzle, and keeping it clean regularly.

Frequently Asked Questions

What is support filament?

Support filaments are temporary filaments to print structures to support compound geometries and overhangs. They tend to be water soluble hence easy to dispose of after printing.

What is the best support filament for PLA?

PVA is the most compatible support filament for PLA because of its water solubility, easy adhesion, and print temperature compatibility.

What is the best support filament for ABS?

HIPS is the best match for ABS filament since both filaments share the same print temperature. Also, HIPS easily melts in solvents such as limonene.

Support structures have made it possible to add innovative yet complicated shapes in our 3D prints which is why industries like aerospace or automotive use it to print functional parts. While printing support structures you must be careful with your choice of support filament.

Consider the factors we have mentioned in the article and make an educated choice. We hope that you find this article useful in this regard.

Keep reading

PETG Hyper Speed: Unlocking new performance levels in 3D printing

At AzureFilm, we believe innovation often starts with curiosity. Our PETG Original filament has long been a reliable choice for makers seeking strength, durability, and consistent print quality. But recently, we asked ourselves: how fast can it really go? To find out, we conducted extensive testing—adjusting printer settings, tweaking slicer parameters, and pushing print speeds [...]

Top 12 Easter STL files

Easter is just around the corner, and we’ve rounded up 12 creative STL files for 3D printing that will make your celebrations even more special. Whether you’re looking to decorate your home, create unique gifts, or add a personal touch to your Easter festivities, these designs have got you covered. Bonus: To make your 3D [...]

The best materials for 3D printing

The advent of 3D printing has undoubtedly changed the world, enabling simple and fast creation of complex objects. Businesses, scientists, independent creators, and all of you who are developing new products can now choose from a variety of materials for your unique projects and create a finished product in just a few hours. 3D printing [...]

Previous post

Previous post