PC ABS: New and improved formula

At AzureFilm, we place great emphasis on continuous development and innovation. This also means that we are constantly thinking about how to improve existing materials and their performance. This time, after receiving your feedback and conducting tests, we have decided to improve our PC ABS filaments.

PC ABS is an incredibly strong automotive-grade material perfect for mechanical parts and technical applications. The addition of polycarbonate (PC) to acrylonitrile butadiene styrene (ABS) creates a material that prints smoothly with nearly perfect interlayer adhesion. The end result is a high-quality print that is lightweight, durable, and has a smooth surface gloss.

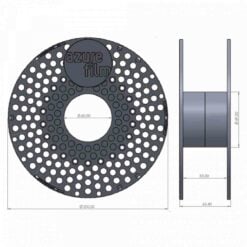

PC ABS filaments

Great interlayer adhesion

One of the standout features of our improved PC ABS formula is its interlayer adhesion. This ensures structural integrity by adhering to the layers of the object firmly. Secondly, proper interlayer adhesion helps with dimensional accuracy by preventing delamination or separation between layers. Thirdly, bonding between layers enhances the overall strength and durability of the object. Moreover, interlayer adhesion is essential for achieving material strength and printing consistency.

A highspeed material

When redesigning this material, we followed the innovation trend and ensured that the filament is capable of printing at high speeds. As 3D printer technology is developing rapidly and offers higher printing speeds, our new PC ABS is designed to meet these demands. It is a high-speed material capable of printing at speeds of up to 350mm/s, and our goal is to offer more filaments with similar capabilities in the future.

Strength and durability

The addition of polycarbonate to ABS makes the material stronger, impact-resistant and durable. Due to its high mechanical performance PC ABS is a reliable and industrial-grade filament.

Mechanical integrity

PC ABS features amazing mechanical strength, which allows the material to withstand high-stress levels without deforming or breaking.

Longevity

This filament retains its strength over time because of its stability and resistance to degradation. The printed parts maintain their performance characteristics throughout their lifespan, reducing the need for frequent replacements.

An extremely resistant material

High heat resistance

Our new and improved formula of PC ABS remains stable and retains its properties when exposed to higher temperatures up to 122°C.

Chemical resistance

PC ABS is resistant to various chemicals, including oils, solvents, and greases. This resistance ensures that printed parts remain unaffected by exposure to harsh substances, enhancing their durability and longevity.

Environmental durability

This material also can resist environmental factors like moisture and its parts keep working for a long time.

Overall better print experience

We are proud to say that our new PC ABS formula offers an enjoyable printing experience because it is easy to work with and you will not have to worry about warping, delamination, and clogging.

Applications of PC ABS

Our new PC ABS filament has improved toughness, high heat resistance, and ease of printing. It can be used for functional prototypes which are crucial for testing products under real-world conditions and making design adjustments.

This material can be used to print automotive components like venting systems and dashboard prototypes. Moreover, it is suitable for consumer products like electronic enclosures for smartphones, tablets, and drones.

Additionally, because of its versatility, PC ABS is great for manufacturing custom fixtures, jigs, and mounts that require durability in industrial settings.

Printing recommendations and technical details

For optimal results, we recommend printing our PC ABS filaments at temperatures between 265°C and 285°C. The recommended printing bed temperature is 110°C. While it’s possible to print without an enclosed printer, we strongly recommend using an enclosure or enclosed 3D printer to ensure the best printing conditions.

For technical properties please access the Technical Data Sheet here.

In conclusion, our new PC ABS offers exceptional strength, durability, and versatility. This material is perfect for various applications including more complex industrial projects.

Mentioned products

Keep reading

PETG Hyper Speed: Unlocking new performance levels in 3D printing

At AzureFilm, we believe innovation often starts with curiosity. Our PETG Original filament has long been a reliable choice for makers seeking strength, durability, and consistent print quality. But recently, we asked ourselves: how fast can it really go? To find out, we conducted extensive testing—adjusting printer settings, tweaking slicer parameters, and pushing print speeds [...]

Top 12 Easter STL files

Easter is just around the corner, and we’ve rounded up 12 creative STL files for 3D printing that will make your celebrations even more special. Whether you’re looking to decorate your home, create unique gifts, or add a personal touch to your Easter festivities, these designs have got you covered. Bonus: To make your 3D [...]

The best materials for 3D printing

The advent of 3D printing has undoubtedly changed the world, enabling simple and fast creation of complex objects. Businesses, scientists, independent creators, and all of you who are developing new products can now choose from a variety of materials for your unique projects and create a finished product in just a few hours. 3D printing [...]

Previous post

Previous post